Contact Us

Evaluating Key Factors When Selecting a Reliable Wheelchair Factory

Checking Out Quality Control

Why Solid Quality Checks Matter

Picking a wheelchair factory? The quality assurance setup is a big deal. A good wheelchair factory makes sure every manual wheelchair and power wheelchair is safe, tough, and works well. Factories with tight quality controls do checks at different steps. They look at raw materials and inspect during assembly. This cuts down on mistakes and makes sure the product meets industry rules.

Quality checks keep users safe. A reliable wheelchair factory also builds customer trust. In a crowded market, focusing on quality makes a wheelchair factory stand out. For manual wheelchairs, reliable wheelchair factories often run tough tests. They stress-test frames and wheels to make sure they hold up over time.

Certifications to Watch For

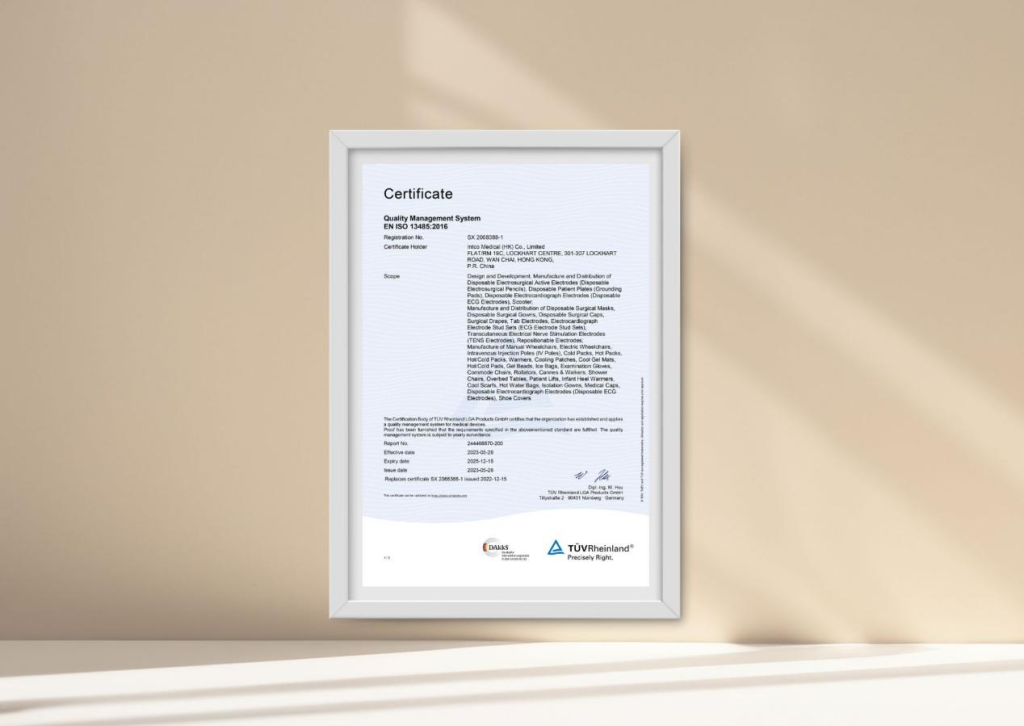

Certifications tell you a good wheelchair factory sticks to global standards. ISO certifications are key—especially ISO 13485. That one’s for making medical devices like wheelchairs. It shows the wheelchair factory’s got processes designed for medical-grade gear.

Also, check for FDA compliance if they’re shipping to the U.S. For Europe, look for CE marking. These mean the products pass strict health and safety tests. Factories that go after these certifications care about making top-notch manual wheelchairs and power wheelchairs.

Digging Into OEM/ODM Service

Personalized Wheelchair Options

People want wheelchairs that fit their exact needs. A good wheelchair factory offers custom designs. You should be able to pick things like seat width or adjustable heights. Maybe you want special armrests or footrests.

Some excellent wheelchair factories make unique solutions for folks with specific mobility issues or medical needs. Custom options make users happier. They also show off the wheelchair factory’s skills. Manual wheelchair factories often nail ergonomic designs that feel comfy for long-term use.

Choices for Materials and Parts

Materials matter a lot. They affect how heavy a wheelchair is, how long it lasts, and how comfy it feels. A solid wheelchair factory lets you choose parts. You might want aluminum frames for something lightweight. Or maybe steel for extra strength. Good upholstery—breathable and easy to clean—should be an option too.

Leading wheelchair factories go beyond basic functionality by offering advanced safety and customization options. For instance, shock-absorbing wheels and anti-tip designs enhance user safety, while the availability of both manual and power drive systems demonstrates their ability to meet diverse needs. These features not only set top manufacturers apart but also reinforce their reliability in a competitive market.

Looking at Supply Chain and Delivery

Fast and Reliable Delivery

When you’re picking a wheelchair manufacturer, the supply chain is huge. Delays in making or shipping wheelchairs can be a real hassle for users who need them ASAP. A good wheelchair factory keeps things moving smoothly. They deliver on time, even for big orders.

Getting High-Quality Materials

The quality of raw materials directly influences the performance and longevity of wheelchairs. Reputable factories prioritize sourcing premium-grade materials from reliable suppliers. Factories committed to sustainability might also opt for eco-friendly materials without compromising on quality. Ethical sourcing practices further enhance the manufacturer’s reputation and align with global trends toward responsible production.

By thoroughly examining these factors—quality control measures, customization options, supply chain efficiency, and material sourcing—you can confidently select a reliable wheelchair factory capable of delivering high-quality products tailored to diverse needs.

Checking After-Sales Support

Warranties and Maintenance Help

A great wheelchair factory doesn’t stop caring once the sale’s done. Warranties are a must. They show the wheelchair factory believes in their manual wheelchairs and power wheelchairs. Look for warranties that cover the frame and parts that wear out. That means they’re confident their products will last.

Maintenance help is just as important. Factories that give you user guides, videos, or even repair visits show they’re in it for the long haul. Keeping wheelchairs in good shape is key to making them last. Some factories even offer maintenance plans with checkups, oiling parts, or swapping out worn bits.

INTCO Medical: A Standout in Wheelchair Making

Brief Introduction of INTCO Medical

As one of the famous brands in the production and manufacture of medical wheelchairs and mobility scooters, INTCO Medical is a high-tech manufacturing company committing to R&D, production and marketing of medical consumables and durable medical equipment with main business covering medical consumables, rehabilitation equipment, physiotherapy care, etc.

Up to now, with a good product reputation, INTCO Medical has been exported products to more than 120 countries and regions in America, Europe, Asia, Africa and Oceania, which is providing practical products and high-quality services to over 10,000 clients.

Jiangsu Intco Medical Products Co., Ltd, a branch of Intco Medical, focuses on the research, production, and marketing of rehabilitation equipment and therapy products. We specialize in manual and electric wheelchairs, mobility scooters, transfer machines, walking aids, commode chairs, and canes. With hundreds of automated machines, we can produce 1,000,000 manual wheelchairs and 100,000 electric wheelchairs annually, serving over 66 countries and regions worldwide.

What Makes INTCO Medical Special

OEM/ODM service is a big win for INTCO. You can choose adjustable seats, comfy designs, or lightweight materials. This makes sure our products fit exactly what users need.

We also care about the environment. INTCO uses eco-friendly materials and energy-saving methods. That fits with the world’s move toward greener production.

After-sales support is another area where INTCO shines. Our warranties cover frames and electronics, giving users confidence in manual wheelchairs and power wheelchairs. Plus, our global service centers make spare parts and repairs easy to get, no matter where you are.

With smart designs, high standards, and great support, INTCO Medical is a leader in the wheelchair world.

FAQ

Q: How can I verify the quality of wheelchairs produced by a factory?

A:

- Ensure certifications like ISO 7176-1 (static strength), ISO 7176-8 (durability), or FDA 510(k) clearance.

- Check for a defect rate below 2%, as reported in customer reviews or third-party audits (industry standard for medical devices).

- Request samples and verify that wheelchairs pass tests like a 100 kg load test for stability or a 15 km/h crash test for power wheelchairs.

- Confirm the factory conducts at least 3 quality control checks per production cycle (e.g., material inspection, assembly, final testing).(Resource from Grok)

Q: Why is customization important when selecting a wheelchair factory?

A:

- Customization addresses diverse user needs, as 60% of wheelchair users require specific adjustments (WHO, 2018). A reliable factory should offer:

- Seat width options ranging from 38 cm to 56 cm to accommodate 95% of adult users.

- Backrest angles adjustable from 90° to 120° for postural support.

- Wheel sizes (e.g., 24″ for manual, 14″ for power) tailored to indoor (1.2 m turning radius) or outdoor use.

Factories with in-house design teams can reduce customization lead times by 20–30% compared to outsourced processes.(Resource from Grok)